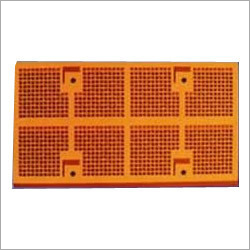

Flip Flop Screen Mats

Price 1200 INR/ Kilograms

MOQ : 4 Kilograms

Flip Flop Screen Mats Specification

- Natural Rubber

- Available/Optional

- Thickness

- 5 mm to 30 mm

- Weight

- Depends on size and thickness

- Size

- Customizable as per requirements

- Feature

- Anti-clogging, Easy Installation, High screening efficiency, Low maintenance

- Tolerance

- 0.5 mm

- Material

- Polyurethane (PU), Natural Rubber, or customized

- Water Absorption

- Low

- Hardness

- Shore A 45-60

- Temperature Resistance

- Up to 80C

- Rubber Type

- Natural Rubber or Polyurethane

- Style

- Flip Flop/Flip Flow

- Part Type

- Screen Panel

- Color

- Black

- Length

- Customizable length

- Surface Finish

- Textured/Matte

- Resistance level

- High wear and tear resistance

- Usage & Applications

- Mining Industries, Coal Washing Plants, Aggregate Processing, Dewatering & Screening, Vibrating Screen Machines

- Width

- 300 mm to 1500 mm

- Components

- Mat, fixing holes, screening slots

- Flame Resistance Level

- Standard grade

- Thermal Conductivity

- Low

- Density

- 1.3 Gram per cubic centimeter(g/cm3)

- Product Type

- Screen Mat

- Tensile Strength

- High tensile strength (as per material standards)

- Application Media

- Wet and dry materials

- Customization Available

- Yes, as per customer requirement

- UV Resistance

- Yes

- Operating Vibration Frequency

- Up to 50 Hz

- Oil Resistance

- Yes

- Slot Opening Range

- 0.5 mm to 45 mm

- Installation Type

- Modular/bolt-on

- Service Life

- Long, varies with material and application

Flip Flop Screen Mats Trade Information

- Minimum Order Quantity

- 4 Kilograms

- Supply Ability

- 100 Kilograms Per Month

- Delivery Time

- 15-30 Days

About Flip Flop Screen Mats

Flip Flop Screen Mats have been used to screen moist or humid materials. These mats are ready to install on machines of all types, sizes, and manufacturers. They are produced from proprietary grades of extremely resilient elastomers with a balanced range of qualities. They allow them to tolerate deformation while maintaining elasticity and dimensional correctness. Flip Flop Screen Mats are effective to use. To provide the best performance in terms of durability, only high-quality elastomers are employed.

Exceptional Screening & Dewatering Performance

Flip Flop Screen Mats deliver high screening efficiency and dewatering capability for a broad range of materials, both wet and dry. Their innovative flip flow design and textured finish combat material clogging, making them highly effective in challenging mining and aggregate processes. The mats anti-clogging nature contributes to uninterrupted operations and greater system output.

Customizable & Durable Construction

Available in widths from 300 mm to 1500 mm and customizable lengths and thicknesses, these mats can be tailored according to your application needs. Built using high-tensile polyurethane or natural rubber, they show excellent resistance to wear, tear, heat, and UV exposure, standing up to prolonged use in demanding industrial settings while minimizing maintenance demands.

FAQs of Flip Flop Screen Mats:

Q: How are Flip Flop Screen Mats installed in screening machines?

A: These mats are designed for modular or bolt-on installation, which enables quick and straightforward setup or replacement. The fixing holes provided align easily with standard vibrating screen assemblies, ensuring a secure and reliable fit on site.Q: What materials are compatible with these mats, and where are they used?

A: Our Flip Flop Screen Mats are suitable for both wet and dry materials, performing exceptionally in mining, coal washing, aggregate processing, and dewatering applications. Their robust design adapts to various screening machines and conditions.Q: How does the customizable range of sizes benefit my operation?

A: With widths from 300 mm to 1500 mm, thickness options of 5 mm to 30 mm, and custom lengths, the mats can be optimized for different screening requirements, improving efficiency and ensuring compatibility with diverse equipment specifications.Q: What is the service life of these mats, and what factors affect longevity?

A: Service life is long but depends on the type of material processed and the application environment. The mats high wear and UV resistance, as well as their sturdy construction, enhance durability, ensuring reliable performance over extended use.Q: Can these screen mats be customized for unique process requirements?

A: Yes, customization is available based on customer specificationsslot size, material composition, dimensions, and installation type can be tailored to meet specific operational needs, providing a perfect fit for your process.Q: What advantages does the flip flop design provide over conventional screen mats?

A: The flip flop or flip flow style enables continuous flexing, which dislodges trapped particles and prevents clogging. This design feature increases screening efficiency, lowers maintenance frequency, and supports higher throughputs in challenging applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS