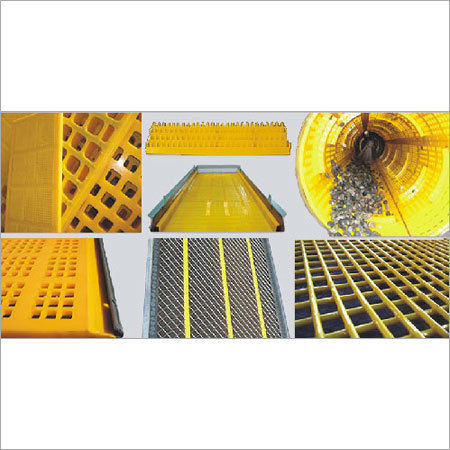

Polyurethane Screen Decks

Price 1200-1500 INR/ Piece

MOQ : 50 Pieces

Polyurethane Screen Decks Specification

- Classification

- Polyurethane Product

- Type

- Screen Decks

- CAS No

- 9009-54-5

- EINECS No

- 618-498-9

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Mining, Quarrying, Aggregate Screening, Sand Screening

- Color

- Yellow

- Form

- Sheet / Panel

- Size

- Customizable (Standard sizes available)

- Material

- High-Tensile Polyurethane

- Abrasion Resistance

- Excellent

- Service Life

- Longer than traditional wire mesh

- Elongation at Break

- 400% - 600%

- UV Resistance

- Yes

- Installation

- Modular & Bolt-On

- Tensile Strength

- 35-55 MPa

- Screen Opening

- 0.1 mm to 100 mm (customized)

- Temperature Resistance

- -30°C to 80°C

- Hardness

- 80-95 Shore A

- Moisture Absorption

- <0.1%

Polyurethane Screen Decks Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 15-30 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Polyurethane Screen Decks

By keeping track with the market development, we are engaged in offering high quality Polyurethane Screen Decks. To meet various requirements of the clients we offer this screen decks as per the specific screening requirement of our valued customers. Provided screen decks are available with rider bars which provides addition screening surface to the oversize material to glide over the rider bars and at the same time the apertures are available to the near size particles for stratification. These Polyurethane Screen Decks are designed with high precision in order to meet the industrial quality standards.

Exceptional Durability and Performance

Polyurethane Screen Decks are built to withstand continuous industrial use, combining abrasion resistance with tensile strength and elongation properties for extended longevity. Their modular and bolt-on installation options make them ideal for rapid maintenance and replacement, minimizing downtime in critical applications. With operational suitability in temperatures ranging from -30C to 80C and high UV stability, they maintain structural integrity and screening efficiency even in challenging outdoor environments.

Tailored Screening Solutions for Multiple Industries

With customizable screen openings from 0.1 mm to 100 mm and options for various thicknesses and sizes, these decks are designed to address specific screening requirements. Whether you are a mining operator, quarry, or aggregate producer, polyurethane screen decks can be adapted seamlessly into your workflow. Their superior material properties and industrial-grade purity ensure optimal performance for a range of screening tasks, backed by the support of experienced distributors, manufacturers, and suppliers across India.

FAQs of Polyurethane Screen Decks:

Q: How are polyurethane screen decks installed?

A: Polyurethane screen decks are designed for quick and simple installation, utilizing modular or bolt-on configurations. Most setups allow for easy replacement and minimal machinery downtime, making them suitable for high-volume production environments.Q: What are the main benefits of choosing polyurethane screen decks for my operation?

A: These decks offer exceptional abrasion and corrosion resistance, longer service life compared to traditional wire mesh, and reduced moisture absorption. Their high tensile strength and flexibility ensure reliable performance in harsh mining and quarrying conditions.Q: When should polyurethane screen decks be used instead of wire mesh?

A: Polyurethane screen decks are recommended when extended service life, reduced maintenance, and high abrasion resistance are crucial. Their temperature resistance and UV stability also make them preferable for outdoor or demanding industrial applications.Q: Where can polyurethane screen decks be applied?

A: They are ideal for use in mining, quarrying, aggregate processing, and sand screening. Customizable opening sizes and formats support a variety of screening processes within these sectors.Q: What is the process for customizing screen opening sizes or panel formats?

A: Customers can specify screen opening dimensions (from 0.1 mm up to 100 mm), thickness, and panel sizes at the time of order. Manufacturers and suppliers in India offer expert consultations to ensure each deck meets precise operational requirements.Q: How do polyurethane screen decks perform against abrasion and harsh weather?

A: They are engineered for excellent abrasion resistance and have very low moisture absorption (<0.1%). Withstanding temperatures from -30C to 80C and offering reliable UV resistance, these decks maintain strength and flexibility even in tough conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS